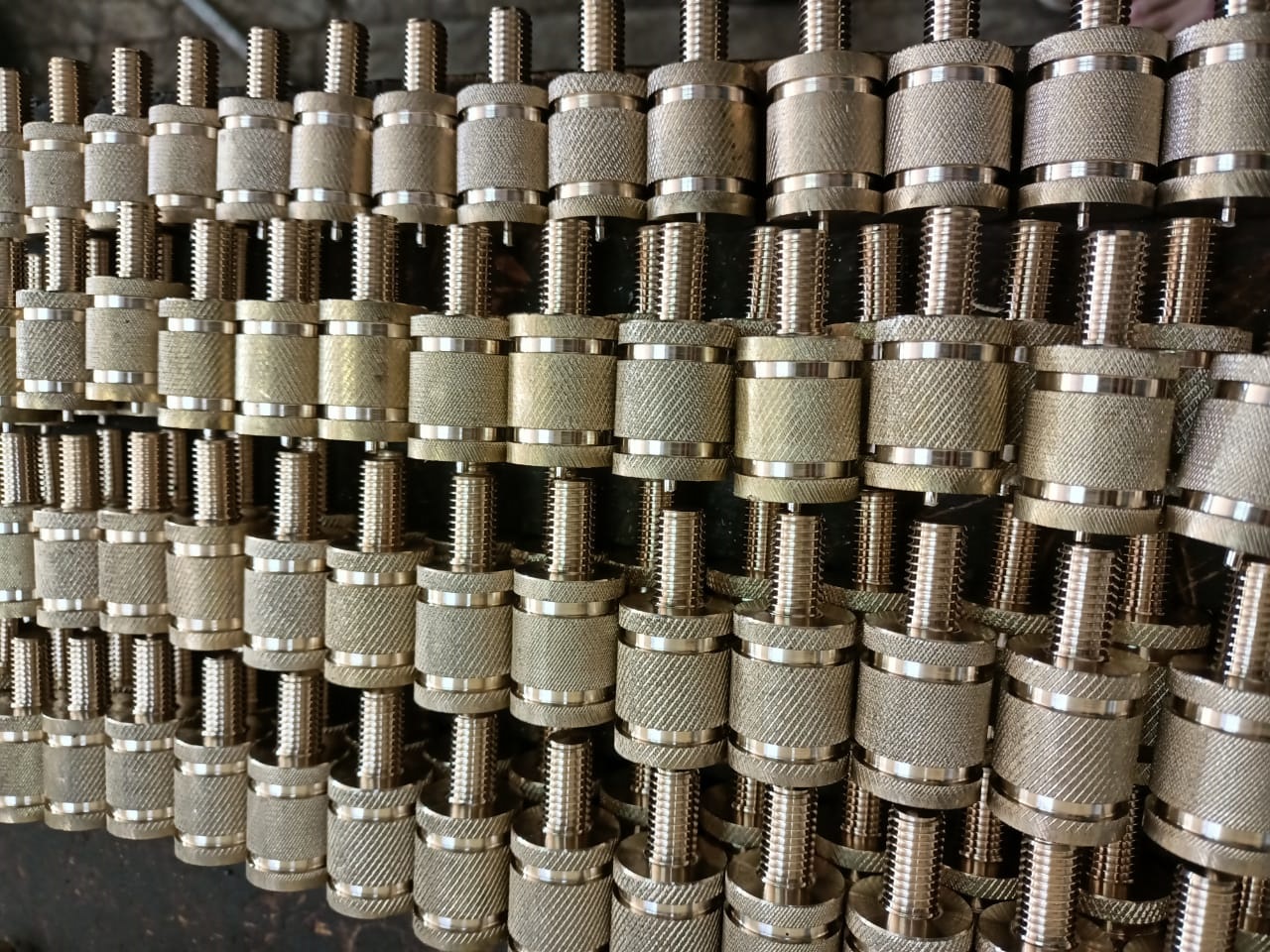

Brass Moulding Inserts are small, precision-engineered components typically used in plastic injection molding. These inserts are made from brass, which provides excellent strength, durability, and resistance to corrosion. Brass moulding inserts are placed into a mold during the injection process to provide a strong, threaded metal insert within a plastic part. This allows for easy attachment and secure fastening, making them ideal for applications in industries such as automotive, electronics, and furniture. Their ability to handle high mechanical stress and provide a reliable threaded connection in plastic components makes them an essential choice for many manufacturers.

Brass moulding inserts offer a variety of benefits, including enhanced durability and the ability to withstand high temperatures and pressure during the molding process. They ensure that plastic parts have a secure, threaded metal insert, which is essential for applications requiring fastening or assembly. The brass material's strength makes these inserts ideal for use in situations where plastic alone might not provide the necessary strength or stability, such as in mechanical assemblies, electrical enclosures, or even consumer products.

Additionally, brass moulding inserts are highly versatile and come in a range of shapes and sizes, making them adaptable to different molding techniques and part designs. Their corrosion resistance ensures a long-lasting solution, even in harsh environments or when exposed to moisture. With their ease of installation and ability to improve the overall strength of plastic components, brass moulding inserts are a popular choice for industries looking to combine the lightweight benefits of plastic with the strength and reliability of metal.